The Fire Lapping Process Involves . The other method, which i prefer, is a more traditional lapping technique using a lead slug, abrasive, and a sturdy rod. Conversion coatings are coatings that use chemicals or a combinations of chemicals and which of the following to change (or convert). The fire lapping process involves: The quickest is to coat a bullet with abrasive and fire it through the bore. How do you decide that lapping is worthwhile and which technique is best to use, hand lap or fire lap? Smoothes the barrel and removes pits and burrs. One of those methods is a process called firelapping, where bullets embedded with abrasive compounds of varying degrees of abrasiveness are shot to. This is called fire lapping and has become quite popular in the last few years. Slightly tapers the barrel from. The fire lapping process accomplishes a number of positive things: Firing cartridges with progressively finer grit abrasive coated bullets, which effectively polishes the bore. For me, the process looks like this:

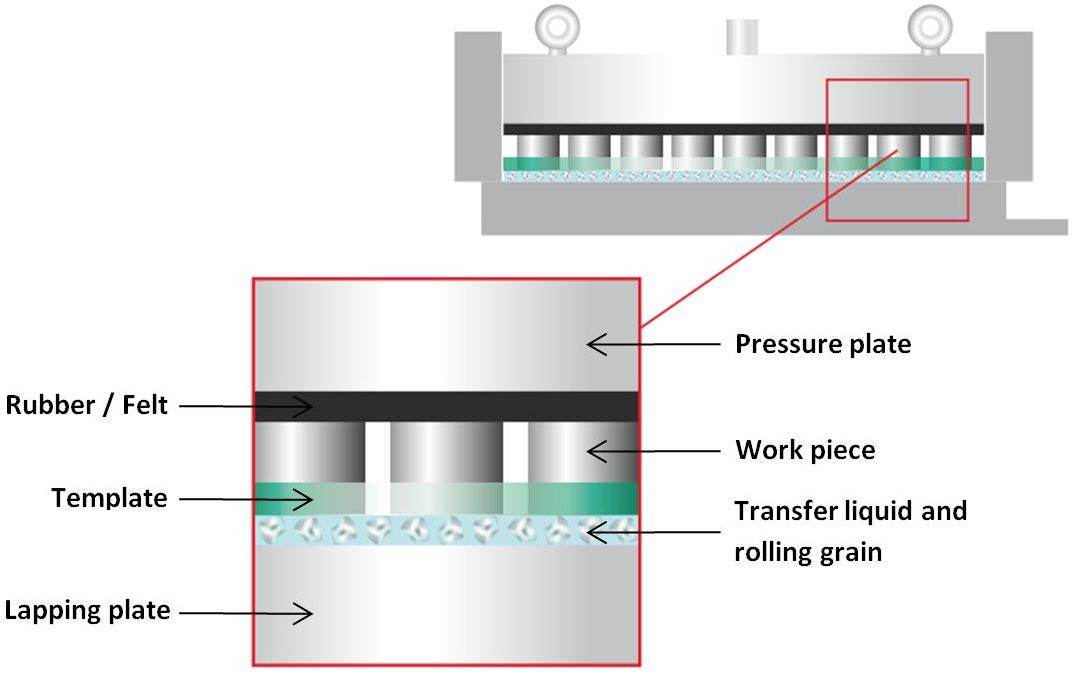

from www.stahli.com

Smoothes the barrel and removes pits and burrs. The quickest is to coat a bullet with abrasive and fire it through the bore. The fire lapping process involves: The other method, which i prefer, is a more traditional lapping technique using a lead slug, abrasive, and a sturdy rod. Firing cartridges with progressively finer grit abrasive coated bullets, which effectively polishes the bore. For me, the process looks like this: This is called fire lapping and has become quite popular in the last few years. Conversion coatings are coatings that use chemicals or a combinations of chemicals and which of the following to change (or convert). Slightly tapers the barrel from. One of those methods is a process called firelapping, where bullets embedded with abrasive compounds of varying degrees of abrasiveness are shot to.

Stähli Lapping

The Fire Lapping Process Involves How do you decide that lapping is worthwhile and which technique is best to use, hand lap or fire lap? How do you decide that lapping is worthwhile and which technique is best to use, hand lap or fire lap? This is called fire lapping and has become quite popular in the last few years. The fire lapping process accomplishes a number of positive things: The fire lapping process involves: For me, the process looks like this: Smoothes the barrel and removes pits and burrs. The other method, which i prefer, is a more traditional lapping technique using a lead slug, abrasive, and a sturdy rod. Slightly tapers the barrel from. Firing cartridges with progressively finer grit abrasive coated bullets, which effectively polishes the bore. The quickest is to coat a bullet with abrasive and fire it through the bore. Conversion coatings are coatings that use chemicals or a combinations of chemicals and which of the following to change (or convert). One of those methods is a process called firelapping, where bullets embedded with abrasive compounds of varying degrees of abrasiveness are shot to.

From singleactions.proboards.com

Fire lapping techniques SingleActions The Fire Lapping Process Involves Firing cartridges with progressively finer grit abrasive coated bullets, which effectively polishes the bore. The other method, which i prefer, is a more traditional lapping technique using a lead slug, abrasive, and a sturdy rod. The fire lapping process accomplishes a number of positive things: How do you decide that lapping is worthwhile and which technique is best to use,. The Fire Lapping Process Involves.

From mungfali.com

Lapping Machine Process The Fire Lapping Process Involves How do you decide that lapping is worthwhile and which technique is best to use, hand lap or fire lap? Smoothes the barrel and removes pits and burrs. The other method, which i prefer, is a more traditional lapping technique using a lead slug, abrasive, and a sturdy rod. The quickest is to coat a bullet with abrasive and fire. The Fire Lapping Process Involves.

From info.loaderpartssource.com

Understanding the Lapping Process Loader Parts Source The Fire Lapping Process Involves Conversion coatings are coatings that use chemicals or a combinations of chemicals and which of the following to change (or convert). One of those methods is a process called firelapping, where bullets embedded with abrasive compounds of varying degrees of abrasiveness are shot to. Smoothes the barrel and removes pits and burrs. The fire lapping process involves: Firing cartridges with. The Fire Lapping Process Involves.

From info.loaderpartssource.com

Understanding the Lapping Process Loader Parts Source The Fire Lapping Process Involves The fire lapping process involves: Firing cartridges with progressively finer grit abrasive coated bullets, which effectively polishes the bore. The quickest is to coat a bullet with abrasive and fire it through the bore. The other method, which i prefer, is a more traditional lapping technique using a lead slug, abrasive, and a sturdy rod. One of those methods is. The Fire Lapping Process Involves.

From encyclopedia.pub

Doublesided lapping Encyclopedia MDPI The Fire Lapping Process Involves Slightly tapers the barrel from. For me, the process looks like this: This is called fire lapping and has become quite popular in the last few years. The quickest is to coat a bullet with abrasive and fire it through the bore. One of those methods is a process called firelapping, where bullets embedded with abrasive compounds of varying degrees. The Fire Lapping Process Involves.

From orro.net

Lapping barrels The Fire Lapping Process Involves One of those methods is a process called firelapping, where bullets embedded with abrasive compounds of varying degrees of abrasiveness are shot to. The fire lapping process involves: Slightly tapers the barrel from. For me, the process looks like this: Conversion coatings are coatings that use chemicals or a combinations of chemicals and which of the following to change (or. The Fire Lapping Process Involves.

From www.stahliusa.com

What is a Lapping Process and what does it consist of doing? The Fire Lapping Process Involves Smoothes the barrel and removes pits and burrs. One of those methods is a process called firelapping, where bullets embedded with abrasive compounds of varying degrees of abrasiveness are shot to. Conversion coatings are coatings that use chemicals or a combinations of chemicals and which of the following to change (or convert). The quickest is to coat a bullet with. The Fire Lapping Process Involves.

From singleactions.proboards.com

Fire lapping techniques SingleActions The Fire Lapping Process Involves The fire lapping process involves: The quickest is to coat a bullet with abrasive and fire it through the bore. Slightly tapers the barrel from. The other method, which i prefer, is a more traditional lapping technique using a lead slug, abrasive, and a sturdy rod. Firing cartridges with progressively finer grit abrasive coated bullets, which effectively polishes the bore.. The Fire Lapping Process Involves.

From www.youtube.com

Lapping plates 4 the lapping process YouTube The Fire Lapping Process Involves The fire lapping process involves: Conversion coatings are coatings that use chemicals or a combinations of chemicals and which of the following to change (or convert). The other method, which i prefer, is a more traditional lapping technique using a lead slug, abrasive, and a sturdy rod. Firing cartridges with progressively finer grit abrasive coated bullets, which effectively polishes the. The Fire Lapping Process Involves.

From www.slideserve.com

PPT Difference between Honing and Lapping Process PrecisionTurned The Fire Lapping Process Involves For me, the process looks like this: Slightly tapers the barrel from. This is called fire lapping and has become quite popular in the last few years. Conversion coatings are coatings that use chemicals or a combinations of chemicals and which of the following to change (or convert). Firing cartridges with progressively finer grit abrasive coated bullets, which effectively polishes. The Fire Lapping Process Involves.

From singleactions.proboards.com

Fire lapping techniques SingleActions The Fire Lapping Process Involves One of those methods is a process called firelapping, where bullets embedded with abrasive compounds of varying degrees of abrasiveness are shot to. How do you decide that lapping is worthwhile and which technique is best to use, hand lap or fire lap? Slightly tapers the barrel from. The other method, which i prefer, is a more traditional lapping technique. The Fire Lapping Process Involves.

From www.stahliusa.com

Centerless Cylindrical Lapping The Fire Lapping Process Involves The other method, which i prefer, is a more traditional lapping technique using a lead slug, abrasive, and a sturdy rod. One of those methods is a process called firelapping, where bullets embedded with abrasive compounds of varying degrees of abrasiveness are shot to. The fire lapping process involves: For me, the process looks like this: Firing cartridges with progressively. The Fire Lapping Process Involves.

From www.gemsons.com

Difference between Honing and Lapping Process PrecisionTurned The Fire Lapping Process Involves This is called fire lapping and has become quite popular in the last few years. Conversion coatings are coatings that use chemicals or a combinations of chemicals and which of the following to change (or convert). The fire lapping process involves: For me, the process looks like this: The other method, which i prefer, is a more traditional lapping technique. The Fire Lapping Process Involves.

From www.researchgate.net

The schematic diagram of a doublesided lapping Download The Fire Lapping Process Involves Slightly tapers the barrel from. Smoothes the barrel and removes pits and burrs. The fire lapping process accomplishes a number of positive things: Firing cartridges with progressively finer grit abrasive coated bullets, which effectively polishes the bore. How do you decide that lapping is worthwhile and which technique is best to use, hand lap or fire lap? Conversion coatings are. The Fire Lapping Process Involves.

From mech4study.blogspot.com

mech4study Lapping Process Principle, Types and Advantages The Fire Lapping Process Involves The fire lapping process involves: How do you decide that lapping is worthwhile and which technique is best to use, hand lap or fire lap? Firing cartridges with progressively finer grit abrasive coated bullets, which effectively polishes the bore. The other method, which i prefer, is a more traditional lapping technique using a lead slug, abrasive, and a sturdy rod.. The Fire Lapping Process Involves.

From www.youtube.com

Fire Lapping YouTube The Fire Lapping Process Involves How do you decide that lapping is worthwhile and which technique is best to use, hand lap or fire lap? Conversion coatings are coatings that use chemicals or a combinations of chemicals and which of the following to change (or convert). The fire lapping process accomplishes a number of positive things: For me, the process looks like this: Smoothes the. The Fire Lapping Process Involves.

From www.researchgate.net

Illustration of lapping process Download Scientific Diagram The Fire Lapping Process Involves The other method, which i prefer, is a more traditional lapping technique using a lead slug, abrasive, and a sturdy rod. Firing cartridges with progressively finer grit abrasive coated bullets, which effectively polishes the bore. Smoothes the barrel and removes pits and burrs. Conversion coatings are coatings that use chemicals or a combinations of chemicals and which of the following. The Fire Lapping Process Involves.

From www.stahliusa.com

The fundamentals of Lapping Processes The Fire Lapping Process Involves For me, the process looks like this: Firing cartridges with progressively finer grit abrasive coated bullets, which effectively polishes the bore. The other method, which i prefer, is a more traditional lapping technique using a lead slug, abrasive, and a sturdy rod. One of those methods is a process called firelapping, where bullets embedded with abrasive compounds of varying degrees. The Fire Lapping Process Involves.